Engine Rebuiling-Performance Engine Rebuilding-Automotive Machine Shop

Performance Automotive ® 475 S Prairie St, Bethalto, IL 62010 (618) - 377-0027.................. Site Designed By AMS Web Designs 1-413-566-0037

Cam Bearing Roller Bearing Conversions

Roller Bearing Conversion and Installation

Typical steel-backed lead Babbitt cam bearings do an excellent job in everyday use but have a number of shortcomings in severe-duty applications. First, in many engine designs, oil is routed from the oil pump to the cam, then to the main bearings, and then to the rod bearings, in that order. In a highly stressed mill, it should be the other way around. The rotating assembly spins twice as fast as the cam and is much more heavily loaded than the cam journals.

Second, whenever radical cam profiles are used, so too are high-pressure valve springs. As they maintain order within the valve train, stiff springs also create plenty of extra friction between the lifters and cam lobes. This is transferred directly to the cam bearings where accelerated wear can result.

Finally, there is the issue of oil temperature. We all know that petroleum-based motor oil can break down if things get too hot. Eliminating much of the friction caused by the spinning cam yields a measurable decrease in oil temperature for added longevity and safety.

All three potential problems are eliminated when you switch to rollerized cam bearings. It eliminates the oil flow leakage around the cam bearings, providing full volume to the rotating assembly, and the superior construction of the roller bearings will handle up to 900 pounds of valve-open spring pressure without problems. (Numbers over 1,000 pounds can be tricky, but you'll never go there unless you're fielding a Pro Stocker.) The reduced friction can drop oil temperature by as much as 20 degrees, allowing dry sump users to carry and pump less

Roller bearing verses needle bearing comparison.

This comparison demonstrates the superior load-bearing capacity of the needle bearings. The larger outside diameter necessitates machining the cam housings and cam tunnel. The altered inside diameter also requires a camshaft with specifically matched journals. Make sure you get in touch with a cam-grinder who can supply you with the right cam before you permanently modify your block

CAMSHAFT NEEDLE BEARINGS

Roller bearings for camshaft tunnels offer increased timing precision, reduced operating friction and the ability to handle higher loads.

By Mike Mavrigian

An alternative to traditional cam bearings is the needle roller bearing, which provides increased stability and durability for extended high-RPM racing applications.

Because of the expense of block machining and the resulting dedication of that block to the use of roller bearings, the move to roller type camshaft bearings isn’t for every build. If the mill is used in short-run drag applications, the modification likely won’t justify itself. If the engine is intended for street use only, switching to roller bearings is just plain stupid and a total waste of money. If however, the engine is being built as a dedicated screamer at its upper end for long periods of time, the move to roller cam bearings makes all the sense in the world. Due to the nature of fitting roller-type camshaft bearings, the block (and camshaft) must be dedicated to the use of these bearings.

DOES THE BLOCK CAM TUNNEL NEED TO BE OVERBORED?

There are a few aftermarket blocks that are already machined for a particular size roller bearing. If you do not have this type of block, then the cam tunnel must be bored to accommodate the specific size of roller bearing that you plan to use. Several O.D. roller bearings are available, including 1.875″, 1.968″ (50mm), 2.125″, 2.165″ (55mm) and 2.362″ (60mm).

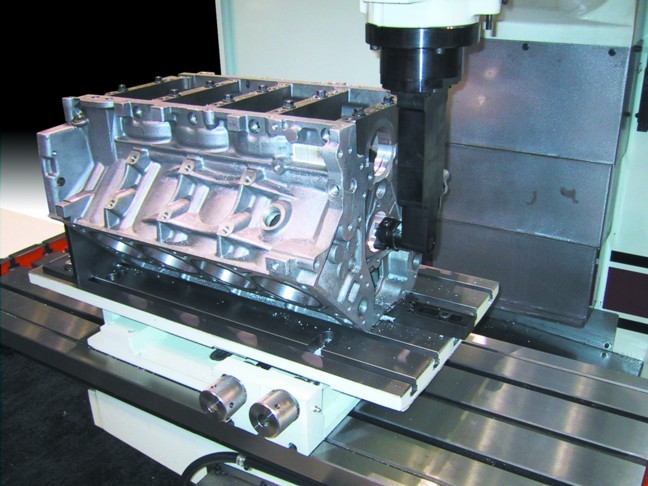

If the block needs to be bored to accept roller bearings, it should be obvious that this requires an extremely precise machining operation, both for finished bore diameter and for bore-to-bore alignment. In general terms, the maximum acceptable runout between individual camshaft bore locations is about 0.0005″.

Bear in mind that in addition to machining the cam bores to accept the roller bearings, the cam tunnel run may require clearancing to allow pass-through of the bearings during installation. This may require tedious grinder work or machine-cutting with a carbide bit.

If circumferential cam bore oil grooves are lost during the over-boring (typically at the number one cam bore location), these grooves must be restored.

Note: since the use of roller cam bearings require all cam bores to be machined to the same diameter, this provides the added installation advantage of being able to install rear cam bearings from the rear of the block.

IF YOU INSTALL ROLLER CAM BEARINGS,

WHAT CAM DO YOU NEED?

If you plan to take advantage of roller cam bearings, you’ll need to order a camshaft that features journals specific to the size of roller bearings that you plan to use.

When installing a roller bearing in an iron block, the bearing cage should have between 0.0005″ to 0.001″ press fit to the cam bore. If you’re installing the roller bearing in an aluminum block, the bearing cage should have between 0.001″ to 0.0015″ press fit to the cam bore.

For proper installation, Comp Cams recommends using a thermal technique as opposed to pressing the bearings into place under ambient temperature. Comp recommends freezing the bearing and heating the block for safe installation to avoid bearing cage damage.

WHAT ABOUT OIL FEED HOLES?

When installing roller type cam bearings, there is usually no need to block or restrict oil feed holes to the cam bearings. Roller type cam bearings usually require only splash lubrication. However, oil feed holes can be blocked off to reduce oil aeration and windage losses, depending on the application. Also, depending on the application (especially when dealing with a production block), oil transfer grooves (such as found in the number one cam bore in a smallblock Chevy) must be restored following the boring operation in order to maintain proper oil flow to the mains.

Since the use of roller-type camshaft bearings reduce camshaft rotating friction, oil-operating temperature should reduce as well. A slight reduction in oil temperature helps to insure greater oil longevity. This issue of friction as it relates to temperature becomes more pronounced in applications that feature aggressive cam profiles and high valve spring rates. Reducing oil-related heat transfer is always a good thing. Since the oil holes in the cam bores are blocked by the roller bearing cages (and by tapping and plugging the holes if desired), more oil is subsequently routed to the crank main bearings and rod bearings, where it’s needed the most.