Engine Rebuiling-Performance Engine Rebuilding-Automotive Machine Shop

Performance Automotive ® 475 S Prairie St, Bethalto, IL 62010 (618) - 377-0027.................. Site Designed By AMS Web Designs 1-413-566-0037

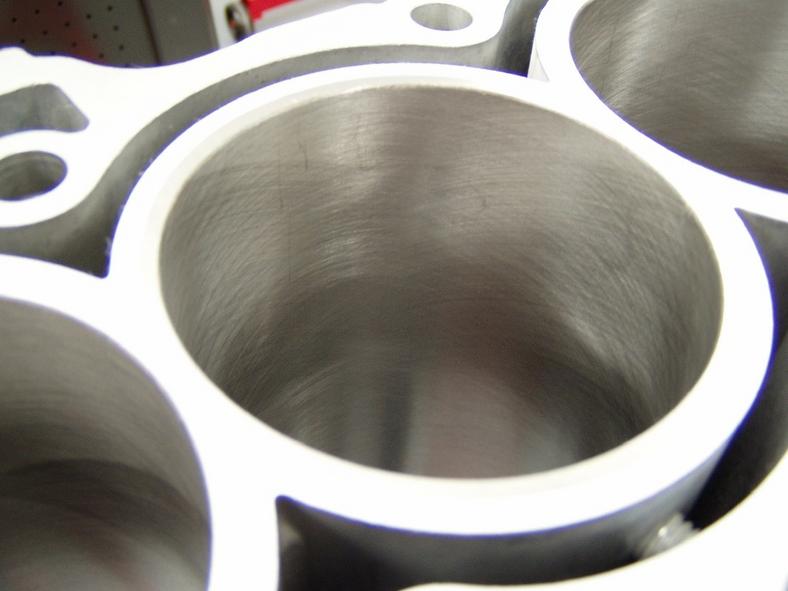

Cylinder Honing

The cylinder honing process takes place after the boring and sleeve process.

The honing process removes the final amount of material left behind after the boring cycle . Cylinder honing also provides the correct "cross hatch" finish for the piston rings to seat and ride on. Providing a perfect finish for the piston rings whether they are molly or cast iron is critical. Theoretically the piston rings glide on a film of oil provided by angled cross hatch pattern of the cross hatch so the rings don't come in contact with the cylinder wall. For high performance application customers Performance Automotive offers Torque Plating of the engine. The torque plate induces the stress of the cylinder head bolted to the block. This provides a true hole to squeeze the most performance out of the block and provides a perfectly round hole as the block is stressed via torque plate, and the main caps are torque from the bottom.

Cyinder Honing with the Rottler H85AX CNC Cylinder Hone

Today's Standards are becoming more demanding

Progressive engine builders must be responsive to the dynamic changes in the industry. With the latest model ring seating requirements and the diverse number of block configurations, the machinist needs the versatility offered by Rottler H Series honing machines. Cylinder finish is becoming a science as the demands continue to grow. Graphical representation of the cylinder finish, such as that displayed on an Abbott-Firestone Curve, provide a qualitative analysis of the characteristics of the surface finish. The Rk family of parameters directly portrays the surface characteristics over a given sampling length.

Features

Another Industry First From Rottler

The H85AX is the first automated cylinder honing machine capable of operating under two automatic program modes.

1. Automatic Stone Feed Out

By setting the number of strokes per feed in conjunction with the total amount to be removed, the operator can hone a cylinder completely unattended. The feed rate can be adjusted anytime during the honing process.

2. Automatic Load Sensing

By setting the desired load pressure in conjunction with the total amount to be removed cylinders can be honed to size accurately, without the need for operator attendance. An industry first! In addition, under high speed automatic operation the machine adjusts to a desirable speed to properly finish the cylinder just before stopping. Enter the load into the computer and the machine automatically maintains this value while it finishes the cylinder.

Setting the stroke is very efficient with the use of the upper and lower limit levers. The positive feed system on Rottler HP machine ensures controlled, precise expansion of the stones.

Rottler has responded to the dynamic needs of today's engine builder by offering the simplest controlled method of finishing cylinders. Turn difficult jobs into dollars. Specific features include:

• Independent Stroke and Spindle drives

Achieve the desired crosshatch efficiently. Stop anywhere in the cylinder.

• Digital Control Operation

Feed settings can be adjusted even while the machine is running.

• Block Clamp Arms

Rottler's superior fixturing allows work pieces without main lines to be fixtures easily.

• Infinitely Variable Speeds and Feeds

Varying the spindle rpm is as easy as the turn of a dial... set your desired operating speed.

Accuracy

Achieve unmatched accuracy and control with Rottler's Heavy Duty Precision Hone Head. This system not only maintains superior accuracy, but is also effective in aggressive stock removal. The Precision Hone Head was developed to provide excellent abrasive tool support and rigidity.

• Provides superior accuracy

• Fast hole geometry correction with minimal stock removal

• Aggressive stock removal from .004 to .012 per minute

• Large capacity for machining diesel block

Cylnder Honing

Special Version Production Machine that can move

automatically in X axis for programmable hole-to-hole

block honing - hones a line of cylinders unattended.

Automatic Lower Crash Protection System

Many Engine Blocks have interference in the lower area of the bores and can damage honing stones and holders. Every

time the H85X starts honing a cylinder, the machine will check bores for interference avoiding potential damage to honing

stones and holders. Variances in lower bores are common. Rottler H85X Control senses lower bore interference prior to

rotation and stroking motion starting at full power, eliminating any stone or holder damage.