Engine Rebuiling-Performance Engine Rebuilding-Automotive Machine Shop

Performance Automotive ® 475 S Prairie St, Bethalto, IL 62010 (618) - 377-0027.................. Site Designed By AMS Web Designs 1-413-566-0037

Engine Block Line Boring Align Boring Cap CNC Right And Drive Align Boring

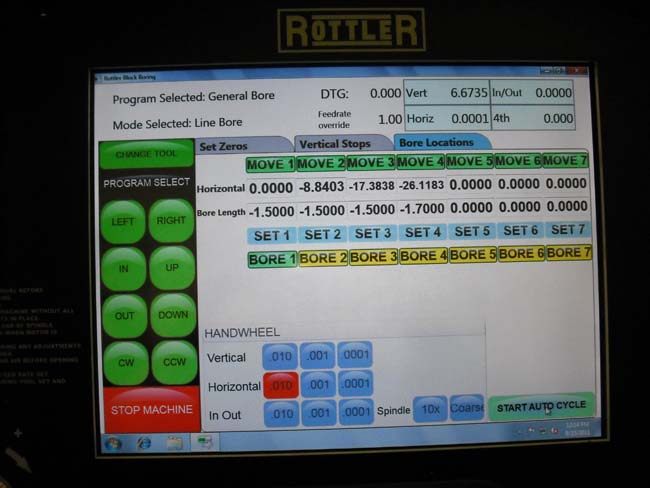

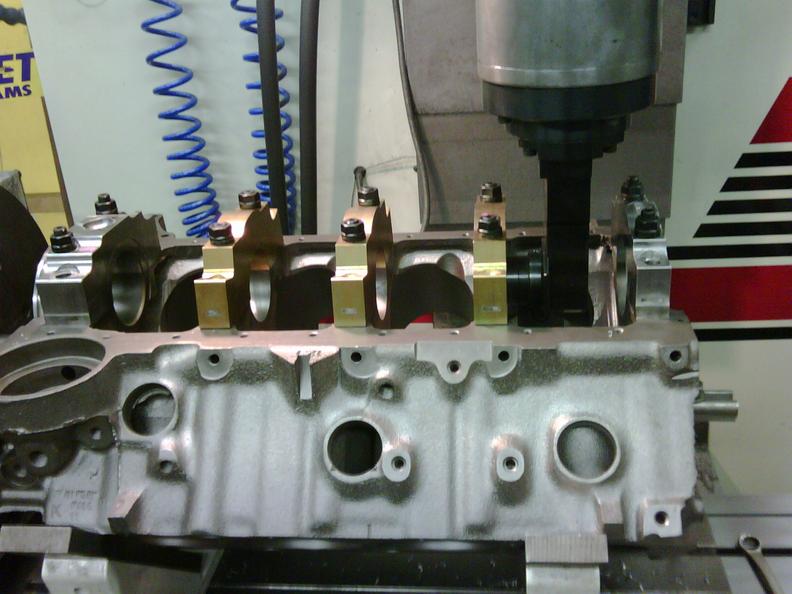

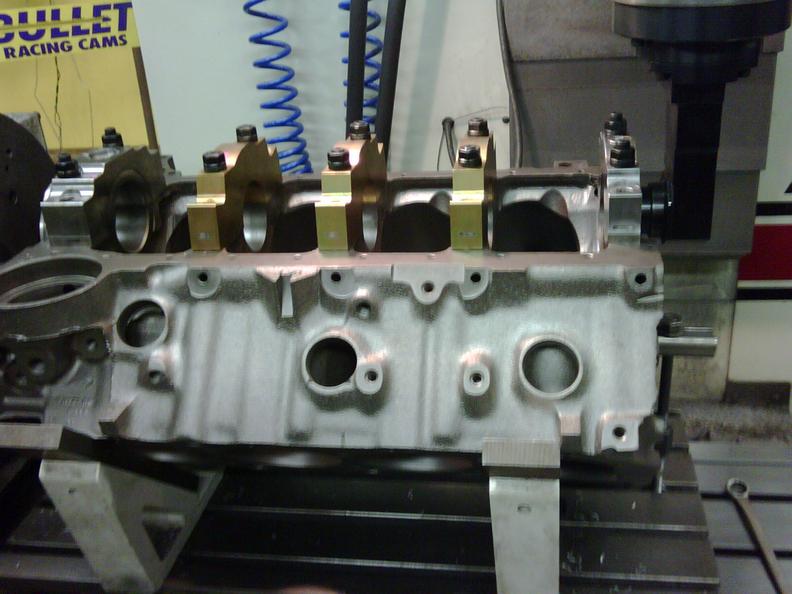

Rottler CNC Engine Block Line Boring process utilizes the right angle drive line bore cutter head. This virtually eliminates bar sag found on traditional line boring machines. The end results is perfect alignment with round and straight main line bores.

Block blue printing starts with the crankshaft main line. This surface is corrected with the CNC line bore process. The block decks and cylinder bores are corrected to the crankshaft and camshaft centerline. The cylinder bores are then bored on center distances to blueprint specs. This process is achieved through the use of a datum fixture that references the crankshaft and camshaft centerline at a true 45 degrees. The block is probed from the centerline then indicated from the dowel location. This enables the bore spacing to be corrected and blue printing the deck surfaces square to the camshaft and crankshaft centerline at a true 45 degree angle is achieved.The dimensions are imputed to the CNC control holding tolerances to 0001. This accuracy is achievable with CNC machinery and specialized Datum plates, and tooling.lock blue printing starts with the crankshaft main line. This surface is corrected with the CNC line bore process. The block decks and cylinder bores are corrected to the crankshaft and camshaft centerline. The cylinder bores are then bored on center distances to blueprint specs. This process is achieved through the use of a datum fixture that references the crankshaft and camshaft centerline at a true 45 degrees. The block is probed from the centerline then indicated from the dowel location. This enables the bore spacing to be corrected and blue printing the deck surfaces square to the camshaft and crankshaft centerline at a true 45 degree angle is achieved.The dimensions are imputed to the CNC control holding tolerances to 0001. This accuracy is achievable with CNC machinery and specialized Datum plates, and tooling.

Engine Block Line Boring